Customer Spotlight: Tinker Air Force Base and Compressed Air Savings

Published by Filter Element Store on Jan 30, 2026

Tinker Air Force Base has been a long-time customer of ours since 2014, so when we saw they were featured by Air Force Materiel Command for major compressed air energy savings, we were pretty excited for them! The story begins at Building 210 of the 76th Maintenance Support Group.

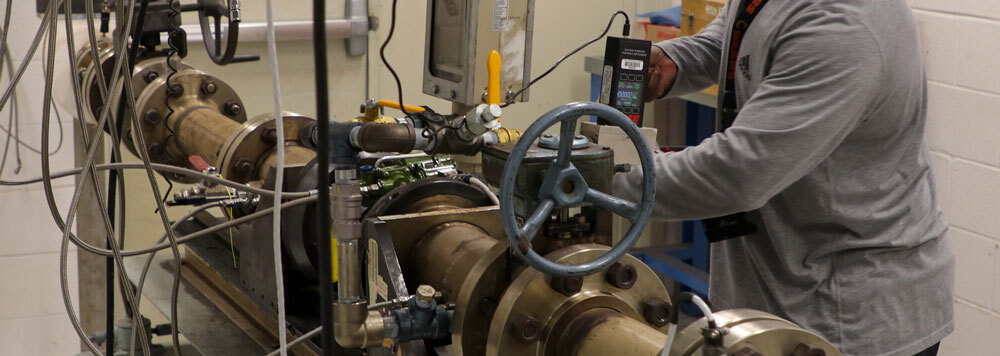

One of their primary jobs is supplying enough airflow to simulate a jet engine in flight, allowing maintainers to properly test aircraft components. Doing that requires moving enormous volumes of air and heating it to temperatures as high as 1,200 degrees Fahrenheit. All of that happens inside the compressor shop, an operation that quietly consumes more energy per square foot than any other building on the base.

The scale of the equipment alone explains why. Their largest compressor is rated at 3,000 horsepower and can deliver up to 8,000 CFM at 320 PSI. That's 12,000 times more power than a home garage air compressor! The compressed air is then heated to up to 1,200°F to simulate jet-engine conditions and dehumidified. It’s a very impressive setup, but it also means energy use adds up very fast. For years, the shop did exactly what it was supposed to do: keep compressed air available at all times.

What changed was not the equipment, but the mindset. When the base energy team reviewed usage data, the compressor shop stood out immediately. The recommendation was simple: turn the equipment off when it isn’t needed. What a novel concept! Tinker AFB is a mission-critical operation running around the clock, and that idea felt pretty risky. Cutting air meant tighter coordination, better scheduling, and a lot more communication between teams.

The expectation was modest. The shop figured they might be able to reduce energy use by about 10 percent. Instead, they saw reductions climb month after month, eventually reaching nearly 50 percent. The savings averaged around $15,000 per month from a shop with just 15 people, which works out to roughly $1,000 per employee, per month. That kind of number tends to get leadership’s attention quickly.

What makes this story especially interesting is that it wasn’t driven by new capital equipment or a major retrofit. It was driven by better awareness of demand, tighter control of runtime, and a willingness to challenge the “leave it on just in case” approach that’s common in compressed air systems everywhere.

We see the same opportunity across industrial facilities all the time. Compressed air is often treated as free once the system is installed, even though it’s one of the most expensive utilities to produce. Tinker’s experience is a great reminder that efficiency gains don’t always start with new compressed air equipment. Sometimes they start with simply running what you already have a little smarter.

New air filters, coalescing filters, oil filters, and air/oil separators don't hurt either... just saying.

Read the full article to learn how Tinker Air Force Base is saving big on compressed air.